High-Precision Heat Treatment for Automotive and Mechanical Parts

🔹 Product Summary

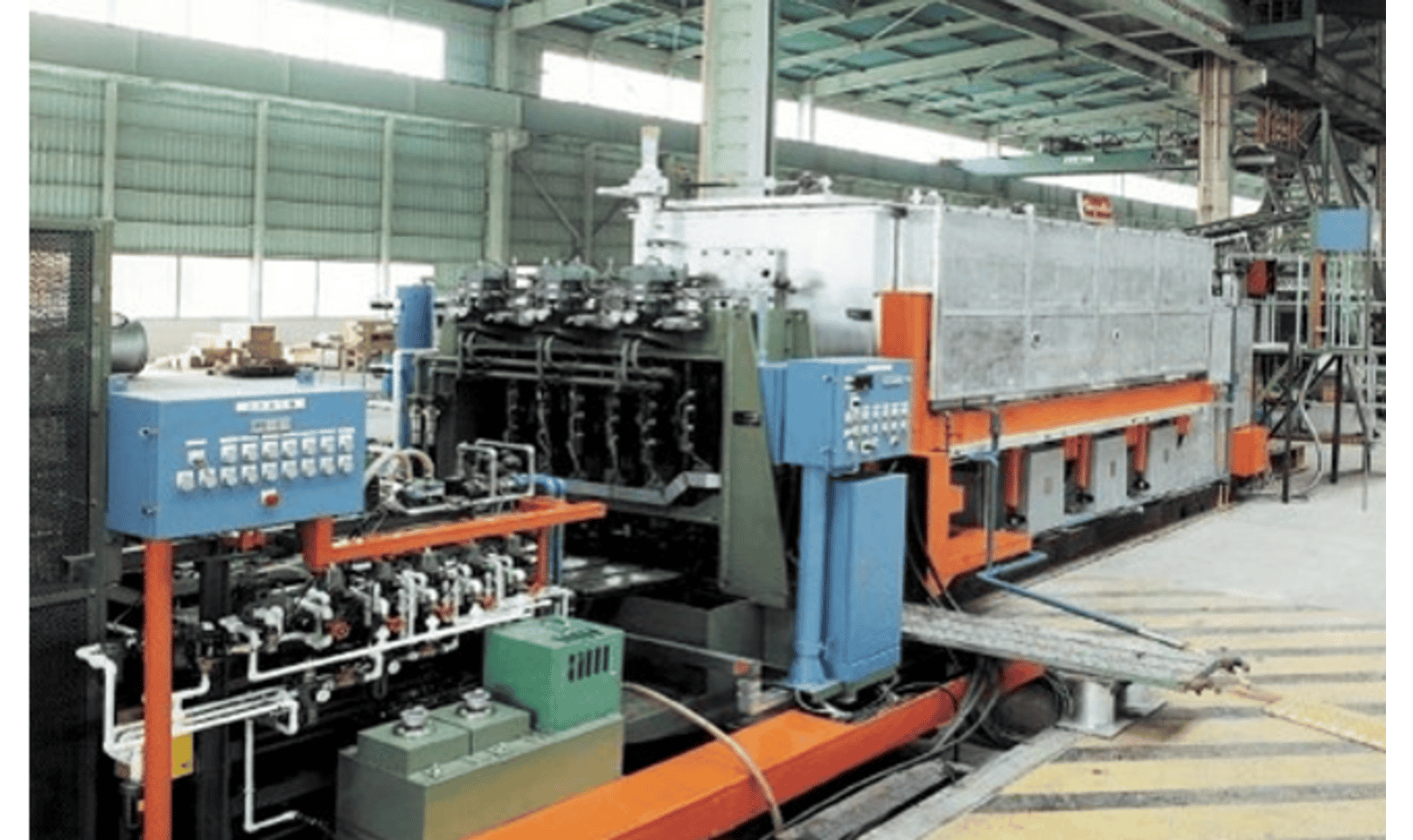

The Press Quenching Machine is engineered for high dimensional accuracy in the heat treatment of gears, bearings, and other precision mechanical components. Using rapid induction heating followed by controlled press quenching, it minimizes deformation while ensuring hardness and product quality.

Compatible with a variety of furnace types—mesh belt, rotary, and roller hearth—the system offers flexible integration into existing production lines. With its energy-efficient design and advanced quality control, it helps reduce operational costs while ensuring consistent, repeatable results.

🔹 Key Features

- ✅ High Dimensional Precision: Minimizes deformation after heat treatment

- ✅ Versatile Furnace Compatibility: Mesh belt, rotary, and roller hearth integration

- ✅ Rapid Induction Heating: Short cycle times with reduced thermal distortion

- ✅ Reliable Quality Control: Ensures product consistency and repeatability

- ✅ Energy Efficiency: Optimized heat treatment with lower operating costs

🔹 Specifications

| Parameter | Description |

| Heating Method | Induction heating |

| Supported Furnaces | Mesh belt, rotary, roller hearth |

| Applications | Press quenching for gears, bearings, precision parts |

| Material Types | Automotive-grade steel, alloy parts |

🔹 Applications

This machine is ideally suited for industries requiring high accuracy and performance in component processing:

- 🚗 Automotive Components: Gears and bearings with tight dimensional tolerances

- 🛠️ Precision Parts: Applications needing micron-level accuracy and consistency

- ⚙️ Complex-Shaped Components: Prevents deformation during heat treatment of intricate parts

Whether your goal is tight tolerance, reduced part distortion, or enhanced hardness, the Press Quenching Machine provides the solution for durable, high-quality output in demanding industrial environments.

For more details, please contact us

PT CHUGAI RO INDONESIA

✉️ chugairo@n-crid.com

📞 +6221-527-9652