High-Precision Thermal Processing for Powders & Granules

🔹 Product Summary

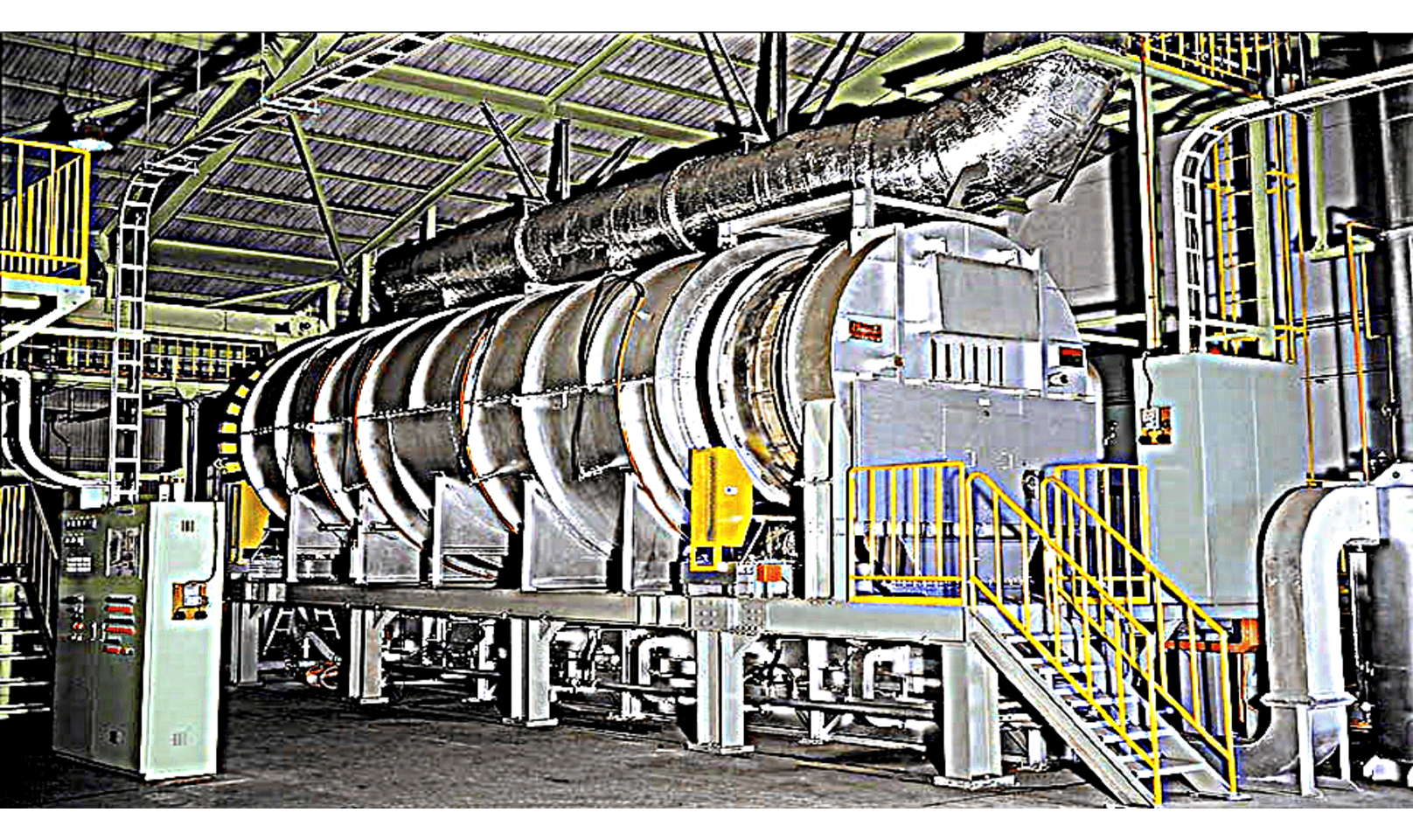

The Multi-Retort Rotary Kiln is a high-efficiency thermal processing system designed for uniform and rapid heating of powders and granular materials such as activated carbon, catalysts, metal powders, and more.

With its multi-tube (multi-retort) design and thin-layer product arrangement, this kiln maximizes heat exchange surface area and ensures even heat distribution, resulting in stable product quality and improved mass production efficiency.

🔹 Key Features

- ✅ Multi-Retort Design for larger heat exchange area

- ✅ Thin-Layer Loading enables uniform, fast heating

- ✅ Supports a Wide Range of Materials: activated carbon, catalysts, ferrites, casting sand, etc.

- ✅ Continuous Operation – ideal for high-volume production

- ✅ Proven stability and repeatability in product quality

🔹 Specifications

| Parameter | Details |

| Materials Processed | Activated carbon, catalysts, resins, chemicals, ferrites, casting sand, metal powders |

| Heating Method | Multi-retort rotary system |

| Key Advantages | Uniform heat distribution, efficient operation, high-quality output |

🔹 Applications

This rotary kiln is used in industries requiring precise and consistent heat treatment, such as:

- 🧪 Chemical Industry – Activated carbon and catalyst processing

- 💡 Electronics Materials – Controlled heating of resins and ferrites

- ⚙️ Metallurgy & Casting – Uniform thermal treatment of metal powders and sand

Its ability to combine production speed, energy efficiency, and heat precision makes it a strategic asset in modern manufacturing.

For more details, please contact us

PT CHUGAI RO INDONESIA

✉️ chugairo@n-crid.com

📞 +6221-527-9652