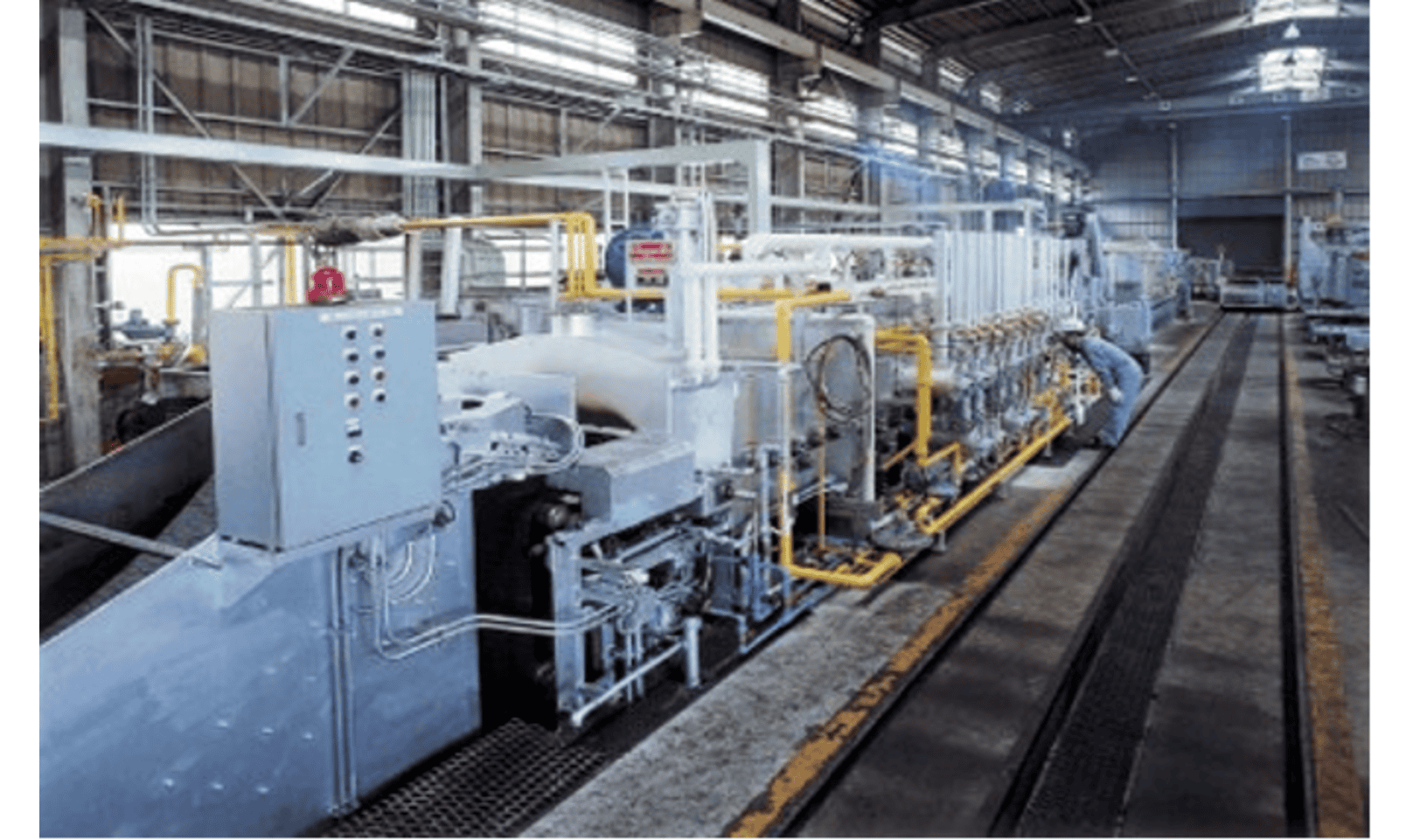

Automated Heat Treatment System for Small Parts with High Energy Efficiency

🔹 Product Summary

The Mesh Belt Furnace is a fully automated heat treatment system engineered for small-sized components. It performs hardening, tempering, and carburizing processes while preserving part shape through a unique natural hardening method—minimizing deformation and ensuring high-precision quality.

With multiple mesh belt sizes, the furnace can accommodate various items such as screws, irregular bearings, and needle bearings. The automation enables smooth operation from material loading to tempering, enhancing productivity. Its energy-efficient design contributes to reducing running costs, making it ideal for cost-conscious manufacturers.

🔹 Key Features

- ✅ Optimized for Small Parts: Designed for screws, bearings, and precision components

- ✅ Shape Preservation: Natural hardening minimizes deformation during processing

- ✅ Fully Automated Operation: From loading to tempering—maximizing productivity

- ✅ Energy Efficient: Cost-saving design through high-efficiency heat usage

🔹 Specifications

| Parameter | Description |

| Functions | Hardening, tempering, carburizing |

| Furnace Type | Mesh Belt Furnace |

| Automation Level | Fully automated |

| Energy Performance | High-efficiency, energy-saving design |

🔹 Applications

The Mesh Belt Furnace is ideal for industries requiring precise thermal processing of small metal parts, including:

- 🔩 Screws and Fasteners: High-precision hardening and tempering

- ⚙️ Bearings: Suitable for irregular and needle bearings, with excellent shape retention

- 🛠 Precision Components: Carburizing treatment to enhance durability

This furnace is a reliable and cost-efficient solution for manufacturers looking to combine automated heat treatment, energy savings, and product integrity.

For more details, please contact us

PT CHUGAI RO INDONESIA

✉️ chugairo@n-crid.com

📞 +6221-527-9652