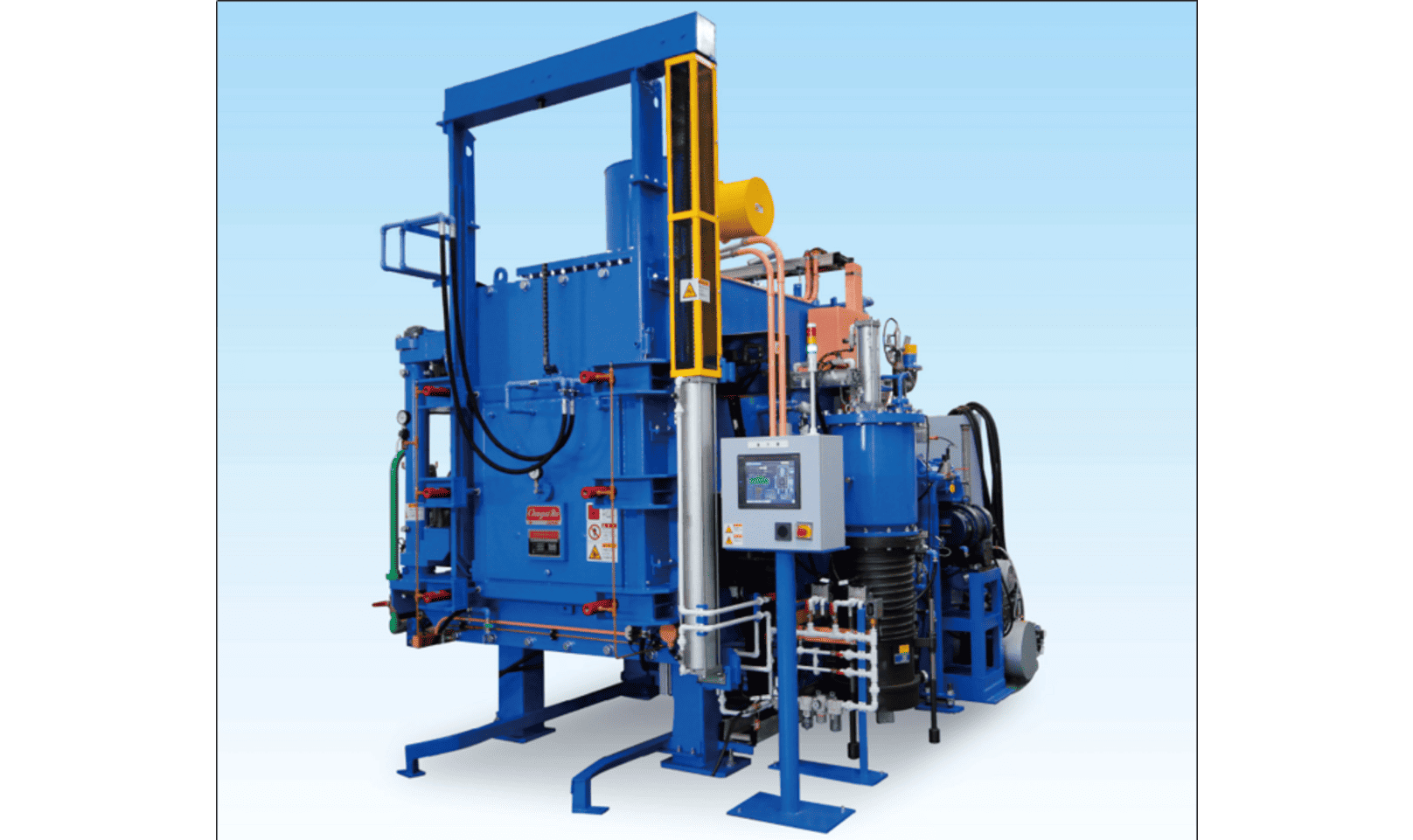

Compact, Energy-Saving Solution for Precision Heat Treatment

🔹 Product Summary

The VFL Series is a low-pressure vacuum furnace specially designed for hardening, brazing, and melting of materials such as tool steel, alloy steel, and stainless steel. Featuring a square vacuum chamber, it enhances space efficiency while reducing gas consumption by approximately 50% compared to conventional systems.

With a 50% smaller installation footprint, it’s ideal for space-constrained facilities. The use of graphite insulation prevents moisture absorption and oxidation—especially important for sensitive materials like SUS (stainless steel).

Its RC fan ensures uniform heating, while the inverter-controlled cooling fan provides energy-optimized, precise cooling tailored to each workpiece.

🔹 Key Features

- ✅ 50% Less Gas Consumption: Thanks to square vacuum chamber

- ✅ Compact Footprint: Requires approx. 50% less installation space

- ✅ Oxidation Protection: Graphite insulation resists moisture and oxidation

- ✅ Uniform Heating: RC fan enhances heat distribution in low to mid-temp ranges

- ✅ Smart Cooling: Inverter-controlled fan adapts cooling to each product

🔹 Specifications

| Parameter | Details |

| Chamber Design | Square-type vacuum chamber |

| Insulation Material | Graphite (oxidation-resistant, low moisture absorption) |

| Heating Method | RC fan for uniform temperature distribution |

| Cooling System | Inverter-controlled fan for energy-efficient cooling |

🔹 Applications

The VFL Series is ideal for industries requiring high-quality heat treatment with limited factory space:

- 🛠️ Tool Steel: Hardening and tempering for durability

- 🧲 Alloy & Stainless Steel: Brazing and melting with clean, consistent finishes

- 🔒 Oxidation-Sensitive Workpieces: Protected by graphite insulation

With its space-saving design, high energy efficiency, and precision thermal control, the VFL Series offers a reliable and cost-effective solution for modern manufacturing environments.

For more details, please contact us

PT CHUGAI RO INDONESIA

✉️ chugairo@n-crid.com

📞 +6221-527-9652