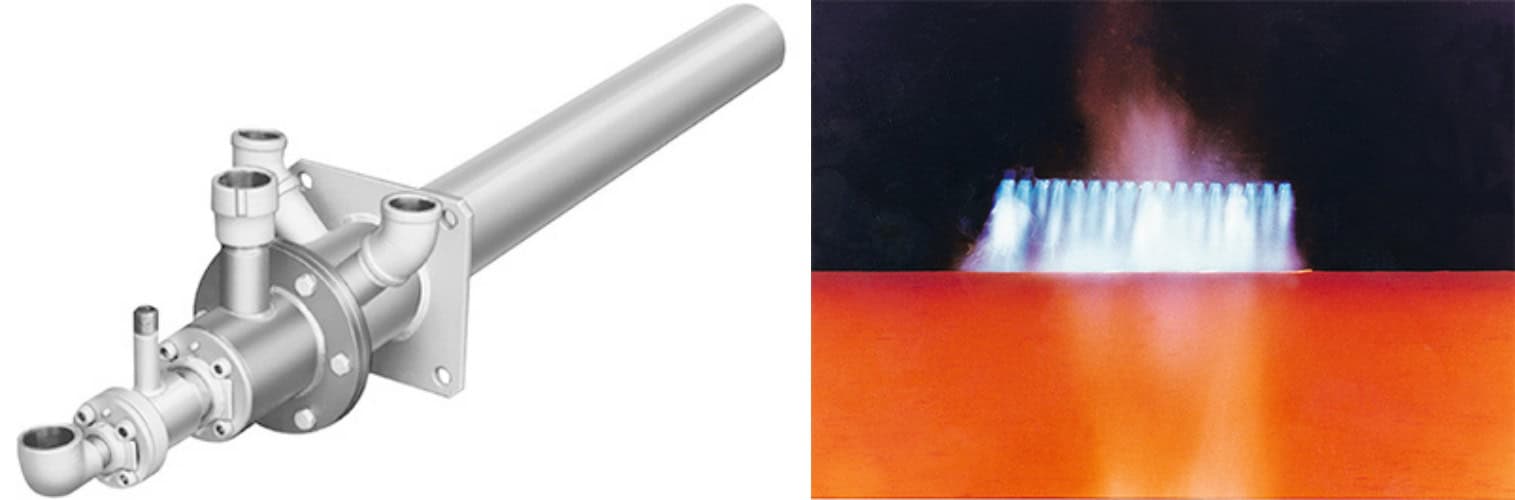

Model CTB oxy-fuel burner

🔹 Summary

The CTB Oxy-Fuel Burner is designed for electric arc furnaces to enhance arc dissolving, increase tapping rate, and reduce power, labor, and operation time. It is available in CTB-1 and CTB-2 models, with CTB-2 allowing oxygen blast. Additional models, OXB and OXF, can be fixed onto furnaces. Numerous assisting firing systems incorporating this burner have been supplied and are well-regarded.

🔹 Key Features

・ Oxy-fuel burner for electric arc furnaces

・ Promotes arc dissolving and increases tapping rate

・ Reduces power consumption, labor, and operational time

・ Available models: CTB-1, CTB-2 (with oxygen blast), OXB, OXF

・ Fuel: various oils, gas, pulverized coal

・ Firing rate: 3,140–16,280 kW

・ Oxygen supply: 600–1,600 m³/hr (combustion), 200–1,600 m³/hr (blast)

🔹 Applications

・ Electric arc furnaces requiring enhanced arc dissolving

・ High-capacity tapping operations

・ Industrial processes using oxy-fuel combustion for efficiency

Model STB troidal burner

🔹 Summary

The STB Toroidal Burner is an oxygen/fuel burner developed by Shell Research Ltd. It is named for its flame pattern, which forms a toroidal (doughnut-shaped) curve, optimizing combustion characteristics.

🔹 Key Features

・ Oxygen/fuel burner

・ Toroidal flame pattern for optimized combustion

・ Developed by Shell Research Ltd.

・ Efficient flame shape for industrial applications

🔹 Applications

・ Industrial furnaces requiring efficient oxy-fuel combustion

・ Processes benefiting from toroidal flame patterns

Model OXL oxy-line burner

Summary

The OXL Oxy-Line Burner is an oxygen/fuel burner designed with linear flames, making it suitable for rapid heating of the end surfaces of steel materials.

🔹 Key Features

・ Oxygen/fuel burner with linear flame pattern

・ Enables rapid heating of steel end surfaces

・ Efficient for focused surface heating

🔹 Applications

・ Steel processing requiring fast end-surface heating

・ Industrial operations needing precise, linear flame application

RESUME TABLE

| Model | Fuel | Firing Rate (kW) | Oxygen Supply (m³/hr) | Key Features | Applications |

|---|---|---|---|---|---|

| CTB Oxy-Fuel | Oil, Gas, Pulverized Coal | 3,140–16,280 | Combustion: 600–1,600Blast: 200–1,600 | Enhances arc dissolving, increases tapping rate, reduces power & labor, multiple models (CTB-1/2, OXB/OXF), oxygen blast option | Electric arc furnaces, high-capacity tapping, oxy-fuel assisted firing systems |

| STB Toroidal | Oxygen/Fuel | – | – | Toroidal flame pattern for optimized combustion, efficient oxy-fuel design | Industrial furnaces needing efficient oxy-fuel combustion |

| OXL Oxy-Line | Oxygen/Fuel | – | – | Linear flame pattern, rapid heating of steel end surfaces | Steel processing, focused end-surface heating |

For more details, please contact us

PT CHUGAI RO INDONESIA

✉️ chugairo@n-crid.com

📞 +6221-527-9652