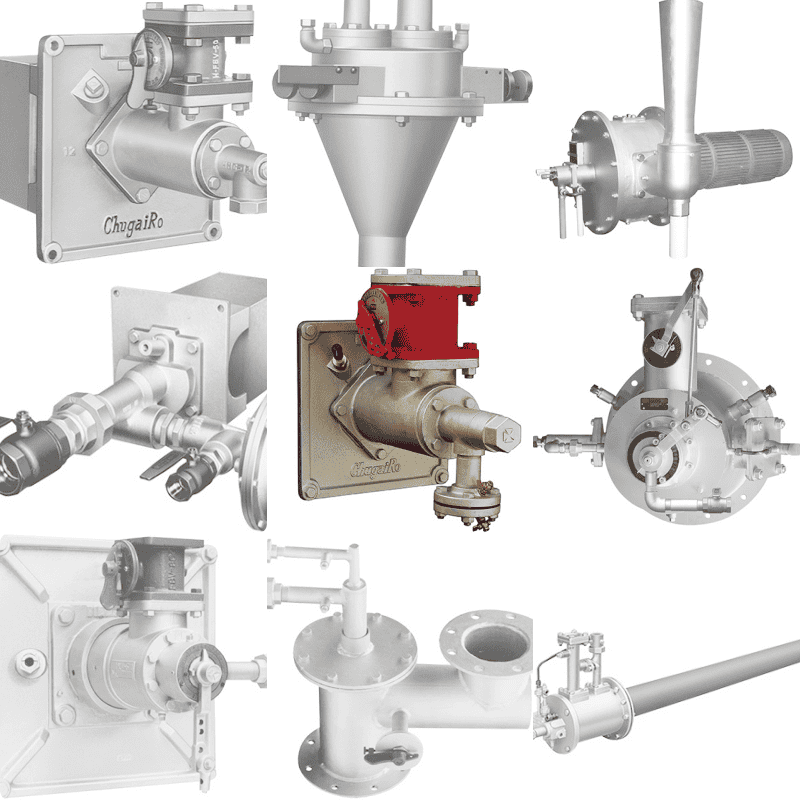

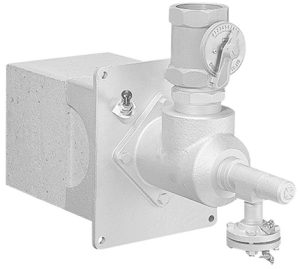

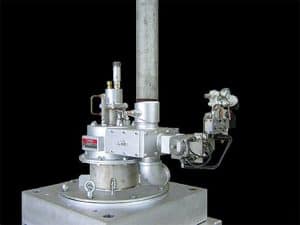

NEOTMG™ throat mix burner

🔹 Summary

The NEOTMG™ Throat Mix Burner Series is a customized product line for small-capacity use, newly added to Chugai Ro’s lineup of general gas burners, the “Model-TMG Throat Mix Gas Burner.”

Equipped with next-generation combustion technology, this series achieves higher performance compared to conventional models, while incorporating advanced safety combustion functions compliant with JIS B 8415-2008, which independently monitor both the main and pilot flames.

With a wide range of sizes available, the NEOTMG™ Series allows selection of the most optimal burner size according to the required firing rate.

🔹 Key Features

・ Next-generation combustion performance with higher efficiency than conventional burners

・ Safety combustion function compliant with JIS B 8415-2008

・ Independent monitoring of main and pilot flames

・ Wide variation in sizes for optimal selection based on firing rate

🔹 Applications

・ Industrial furnaces requiring compact yet efficient gas burners

・ Manufacturing processes demanding safe, precise combustion control

・ Energy-conscious facilities aiming for advanced burner performance

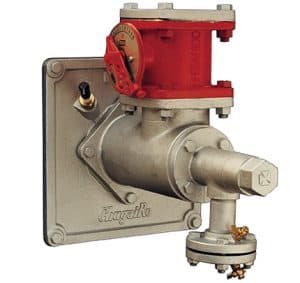

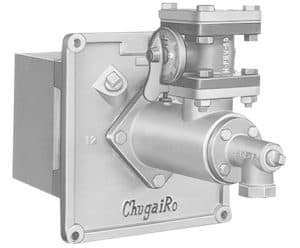

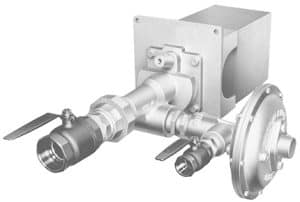

Model TMG throat mix burner

🔹Summary

The Model TMG Throat Mix Gas Burner is a general-use industrial gas burner with a turn-down ratio of 10:1, delivering stable and efficient combustion across a wide firing range. Designed for ease of operation, it achieves low excess air combustion by using a single valve and provides safe, reliable ignition through direct electric spark plug ignition.

🔹Key Features

・ Turn-down ratio of 10:1 for flexible combustion control

・ Low excess air combustion across the full firing range

・ Single-valve operation for simplified control

・ No backfire for stable and safe operation

・ Direct electric ignition using a spark plug

🔹Firing Rate by Model

| Model | Firing Rate (kW) |

|---|---|

| TMG-1B | 18.6 |

| TMG-3B | 36.6 |

| TMG-6B | 72.7 |

| TMG-12B | 145 |

| TMG-25B | 291 |

| TMG-50B | 581 |

| TMG-75B | 872 |

| TMG-100B | 1163 |

🔹Applications

・ Industrial furnaces requiring flexible firing rate control

・ Manufacturing processes demanding efficient and stable combustion

・ Facilities seeking reliable burners with safe ignition systems

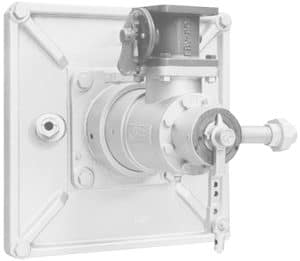

Hot-TMG throat mix burner for high temperature air

🔹 Summary

The Hot-TMG™ Throat Mix Burner is specially engineered for use with high-temperature preheated air, supporting applications up to 500℃. Equipped with the advanced EBC-i automatic air ratio control system, it guarantees stable low excess air combustion even when firing rates or air temperatures fluctuate.

🔹 Key Features

・ Supports preheated air up to 500℃

・ Stable low excess air combustion with EBC-i automatic air ratio control

・ Maintains efficiency across varied firing rates and air temperatures

・ High-performance design ensures reliable operation under demanding conditions

🔹Specifications

・ Air Pressure: 4.5 kPa

・ Air Temperature: 350℃ (operational condition)

・ Maximum Preheated Air: 500℃

・ Burner Type: Throat Mix Gas Burner

🔹 Firing Rate

| Model | Firing Rate (×kW) |

|---|---|

| H-TMG – 3B | 25.6 |

| H-TMG – 6B | 51.2 |

| H-TMG – 12B | 102 |

| H-TMG – 25B | 203 |

| H-TMG – 50B | 407 |

🔹Applications

・ Industrial furnaces requiring high-temperature combustion air

・ Heat treatment systems with variable preheated air supply

・ Processes demanding stable and efficient combustion at high operating temperatures

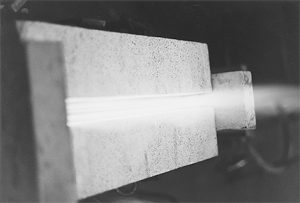

Model HMG high-momentum burner

🔹 Summary

The Model HMG High-Momentum Burner is designed to generate a high-speed flame with large momentum, effectively agitating furnace air. This ensures uniform and rapid heating, making it highly suitable for processes that require stable temperature distribution and minimal oxidation.

🔹 Key Features

・ High-momentum flame for effective furnace air agitation

・ Uniform and rapid heating performance

・ Extremely low generation of free O₂ under reducing combustion → ideal for oxidation-free heating applications

・ Capable of using preheated air up to 500℃

・ Stable operation under demanding thermal environments

🔹 Specifications

・ Air Pressure: 5 kPa

・ Air Temperature: 20℃ (standard condition)

・ Maximum Preheated Air: 500℃

・ Application Type: High-Momentum Gas Burner

🔹Firing Rate

| Model | Firing Rate (× kW) |

|---|---|

| HMG – 6 | 70 |

| HMG – 9 | 105 |

| HMG – 12 | 140 |

| HMG – 18 | 209 |

| HMG – 25 | 290 |

| HMG – 40 | 465 |

| HMG – 60 | 698 |

🔹 Applications

・ Oxidation-free heating processes

・ Furnaces requiring uniform temperature distribution

・ Rapid heating applications

・ Heat treatment systems with high preheated air supply

Immersion tube Self Regenerative Gas Burner

🔹Summary

The Immersion Tube Self Regenerative Gas Burner (ISRG) is a compact, mono-block regenerative burner specifically designed for immersion tube applications. It integrates a pilot burner and an air/exhaust switching valve, eliminating the need for an induced draft fan (IDF). With its space-saving design and regenerative alumina ball media, the ISRG reduces system size and cost while ensuring excellent combustion efficiency, durability, and reliability.

🔹Key Features

・ Compact mono-block construction with integrated pilot burner and air/exhaust valve

・ No need for an exhaust gas suction fan (IDF)

・ Selectable thermal storage within the immersion tube

・ Regenerative alumina ball media for high heat and corrosion resistance

・ Cost-efficient alternative to conventional regenerative systems

🔹Technical Specifications

・ Regenerative Media: Alumina ball

・ Air/Exhaust System: Integrated valve (no IDF required)

・ Construction: Compact mono-block unit

・ Usage: Immersion tube type furnaces

🔹Applications

・ Nonferrous metal melting furnaces

・ Holding furnaces with immersion tubes

・ Facilities where conventional regenerative systems cannot be installed

Model SRMG™ Recu-burner

🔹Summary

The SRMG™ Recu-burner is a fuel-saving high-speed flame burner with a built-in recuperator. Its compact design enables efficient heat recovery and simplified operation. The burner can be controlled with time-proportional ON-OFF control, removing the need for complex control devices.

🔹Key Features

・ Built-in recuperator for enhanced fuel efficiency

・ High-speed flame ensuring effective heating performance

・ Simple operation with time-proportional ON-OFF control

・ Compact and cost-effective construction

・ Stable combustion under continuous operation

🔹Specifications

・ Air Pressure: 6 kPa

・ Air Temperature: 20℃

・ Burner Type: High-Speed Flame Gas Burner with Recuperator

🔹Applications

・ Fuel-saving heating processes

・ Continuous-operation heat treatment systems

・ Industrial furnaces requiring simplified burner control

・ Installations where compact burner design is preferred

Model VB Low Pressure Velocity Burner

🔹Summary

The Model VB Low Pressure Velocity Burner is a premixing burner designed to induce fuel gas proportionally by low-pressure air. Its design allows the firing rate to be adjusted simply by controlling the air pressure without altering the air-fuel ratio. This makes it versatile and suitable for a wide range of applications, from high-temperature to low-temperature furnaces.

🔹Key Features

・ Premixing burner utilizing low-pressure air for fuel induction

・ Proportional adjustment of firing rate via air pressure control

・ Stable air-fuel ratio maintained across different firing rates

・ Flexible use for various furnace temperature ranges

・ Simple operation and cost-effective control

🔹Specifications

・ Air Pressure: 6 kPa

・ Application Type: Low Pressure Velocity Premixing Burner

🔹Firing Rate Range

| Model | Firing Rate (×kW) |

|---|---|

| 2205VB ~ 2209VB | 57 ~ 185 |

| 2210VB ~ 2213VB | 236 ~ 353 |

| 2313VB ~ 2318VB | 415 ~ 733 |

| 2418VB ~ 2426VB | 863 ~ 1488 |

| 2526VB ~ 2532VB | 1686 ~ 2320 |

| 2632VB ~ 2638VB | 2512 ~ 3047 |

🔹Applications

・ High-temperature furnaces

・ Low-temperature furnaces

・ Industrial heating systems requiring flexible firing rate adjustment

・ General-purpose combustion systems

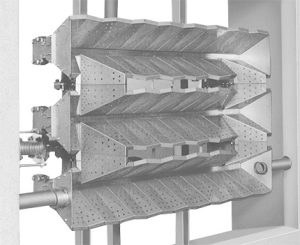

Model DGB Double-Cone Burner

🔹Summary

The Model DGB Double-Cone Burner is a low-temperature oven burner designed with a high turn-down ratio of 20:1. It integrates a built-in gas and air flow regulator, enabling low excess air combustion across the full range of firing rates. The burner is easily operated with a single lever, ensuring stable and efficient performance.

🔹Key Features

・ High turn-down ratio of 20:1 for flexible operation

・ Built-in gas and air flow regulator for precise control

・ Low excess air combustion over full firing rate range

・ Simple operation using a single lever mechanism

・ Stable performance for low-temperature furnace applications

🔹Specifications

・ Air Pressure: 6 kPa

・ Air Temperature: 40℃

・ Burner Type: Low-Temperature Oven Burner with Double-Cone Design

🔹Firing Rate Table

| Model | Firing Rate (× kW) |

|---|---|

| DGB-15D | 174 |

| DGB-30D | 348 |

| DGB-60D | 698 |

| DGB-80D | 930 |

| DGB-100D | 1160 |

| DGB-140D | 1630 |

🔹Applications

・ Low-temperature ovens

・ Industrial furnaces requiring flexible firing rate control

・ Heating processes with demand for efficient low excess air combustion

・ Systems benefiting from simplified single-lever operation

Model HFB™ High-Flame Burner

🔹Summary

The Model HFB™ High-Flame Burner is a nozzle-mix burner designed to achieve rapid gas-air mixing through swirling air at the burner tip. This results in a wide, radially spreading flat flame, ideal for uniform heating. Two variations are available: HFB™ for normal temperature air and H-HFB™ for applications utilizing preheated air up to 500℃.

🔹Key Features

・ Nozzle-mix design ensuring rapid gas-air mixing

・ Flame spreads radially to form a flat flame for uniform heating

・ Available in two models:

- HFB™: for normal air temperature operation

- H-HFB™: for preheated air up to 500℃

・ Compact, reliable design suitable for various heating applications

・ Energy-efficient with stable combustion performance

🔹Specifications

・ Air Pressure: 3 kPa

・ Air Temperature: 20℃ (HFB™), up to 500℃ (H-HFB™)

・ Burner Type: Nozzle-mix, high-flame flat burner

🔹Firing Rate Table

| Model | Firing Rate (×kW) |

|---|---|

| HFB-1WR | 11.6 |

| HFB-2WR | 23.3 |

| HFB-3WR | 34.9 |

| HFB-5WR | 58.1 |

| HFB-10WR | 116 |

| HFB-15WR | 174 |

| HFB-20WR | 233 |

| HFB-30WR | 349 |

| HFB-40WR | 465 |

🔹Applications

・ Heat treatment furnaces requiring flat flame distribution

・ Surface heating in industrial furnaces

・ Ovens and kilns requiring uniform temperature profiles

・ Systems utilizing either normal or preheated combustion air

Model GPL Proportional Adjustment Burner

🔹Summary

The Model GPL Proportional Adjustment Burner is a nozzle-mix burner designed to achieve proportional adjustment of gas and air through the operation of a single lever. Its standardized mounting size and flame characteristics make it interchangeable with the PLB oil burner, allowing the combustion chamber to operate with either gas or oil simply by switching the burner.

🔹Key Features

・ Nozzle-mix burner with single-lever proportional control of gas and air

・ Standardized mounting size and flame characteristics with PLB oil burner

・ Enables dual-fuel flexibility (gas or oil) with simple burner replacement

・ Ensures stable combustion and efficient operation

・ Suitable for versatile heating applications requiring proportional adjustment

🔹Specifications

・ Burner Type: Nozzle-mix, proportional adjustment. Air pressure : 6kPa

・ Fuel: Gas (with option to switch to oil using PLB burner)

・ Adjustment: Proportional control via single lever

・ Interchangeability: Compatible with PLB oil burner combustion chamber

🔹Firing Rates

| Model | Firing Rate (×kW) |

|---|---|

| GPL – 1A | 87 |

| GPL – 3A | 145 |

| GPL – 5A | 331 |

| GPL – 10A | 564 |

| GPL – 20A | 1233 |

🔹Applications

・ Furnaces requiring flexible fuel options (gas/oil)

・ Industrial heating systems with proportional flame control

・ Process heating where dual-fuel operation is advantageous

・ Systems requiring easy adjustment of combustion characteristics

Model NG Nozzle Mix Burner

🔹 Summary

The Model NG Nozzle Mix Burner is a general-purpose burner designed for combustion with fuel gas and air at low pressures. Its simple structure combined with a wide turn-down ratio makes it versatile for various applications. Additionally, the NG-L model is available for large capacity needs, providing firing rates up to 5810 kW.

🔹 Key Features

・ Simple and robust design for ease of operation and maintenance

・ Compatible with fuel gas and low-pressure air

・ Wide turn-down ratio for flexible firing rate control

・ NG-L model available for higher capacity operations

・ Suitable for a wide range of industrial applications

🔹 Specifications

・ Air Pressure: 2.5 kPa

・ Type: Nozzle Mix Burner

・ Firing Rate (NG-L Model): 1740 – 5810 kW

🔹 Models and Firing Rates

| Model | Firing Rate (×kW) |

|---|---|

| NG-4D | 46.5 |

| NG-8D | 93.0 |

| NG-15D | 174 |

| NG-30D | 349 |

| NG-60D | 698 |

| NG-100D | 1160 |

🔹 Applications

・ General industrial furnaces

・ Heating systems requiring flexible firing capacity

・ Large-scale combustion systems (using NG-L model)

・ Processes needing reliable low-pressure combustion

Model RFB Roof Burner

🔹 Summary

The Model RFB Roof Burner is designed for installation on the ceiling or sidewall of a reheat furnace. It heats the material by radiation from the burner tile and is capable of utilizing preheated air up to 700℃. Two versions are available: the standard RFB-I and the RFB-II, which allows switching the flame form from swirled wide to no-swirled wide or vice versa.

🔹 Key Features

・ Ceiling or sidewall mounting for reheat furnaces

・ Heats primarily by radiation from burner tile

・ Operates with preheated air up to 700℃

・ Two variations: RFB-I (standard) and RFB-II (adjustable flame form)

・ Durable structure suitable for continuous industrial use

🔹 Specifications

・ Air Pressure: 3 kPa

・ Air Temperature: 450℃

・ Type: Roof Burner

🔹 Models and Firing Rates

| Model | Firing Rate (×kW) |

|---|---|

| RFB-2 | 116 |

| RFB-3 | 186 |

| RFB-4 | 290 |

| RFB-7 | 465 |

| RFB-10 | 698 |

🔹 Applications

・ Reheat furnaces in steel and metallurgical industries

・ Processes requiring ceiling or sidewall mounted burners

・ High-temperature heating with preheated combustion air

・ Applications demanding adjustable flame characteristics

Model CRB Concentric Radiant Tube Unit

🔹 Summary

The Model CRB Concentric Radiant Tube Unit is a unitized straight radiant tube heater that integrates a low NOx burner with a built-in recuperator and a radiant tube. It ensures uniform heating of the material and is designed for furnace operations up to 950℃. The radiant tube can be easily replaced with an electron tube, providing flexibility and ease of maintenance.

🔹 Key Features

・ Unitized design combining burner, recuperator, and radiant tube

・ Low NOx burner for environmentally friendly operation

・ Provides uniform heating inside the furnace

・ Operates with furnace temperatures up to 950℃

・ Easy replacement of radiant tube with an electron tube

・ Robust and reliable for continuous industrial use

🔹 Specifications

・ Air Pressure: 4.5 kPa

・ Air Temperature: 20℃

・ Type: Concentric Radiant Tube Heater

🔹 Models and Firing Rates

| Model | Firing Rate (kW) |

|---|---|

| CRB-80 | 11.6 |

| CRB-100 | 23.3 |

| CRB-125 | 33.7 |

| CRB-150 | 46.5 |

🔹 Applications

・ Industrial furnaces requiring uniform material heating

・ High-temperature processes up to 950℃

・ Applications prioritizing low NOx emissions

・ Operations needing radiant tube systems with easy maintenance

Model CFB-II Slit Nozzle Burner

🔹 Summary

The Model CFB-II Slit Nozzle Burner generates a high-speed, straight horizontal flat flame through a slit-shaped burner tile outlet. With its large flame surface area, it delivers excellent uniform heating performance. It is highly suitable for direct non-oxidizing heating since the free oxygen concentration remains very low, even under sub-stoichiometric combustion conditions.

🔹 Key Features

・ Produces high-speed horizontal flat flame

・ Large flame surface area ensures uniform heating

・ Suitable for direct non-oxidizing heating

・ Very low free oxygen concentration, even below stoichiometric combustion

・ Available in two models: C-CFB-II (ambient air) and H-CFB-II (preheated air up to 500℃)

🔹 Specifications

・ Air Pressure (C-CFB-II): 3 kPa (for ambient air)

・ Air Pressure (H-CFB-II): 5 kPa (for preheated air)

・ Maximum Preheated Air Temperature: 500℃

・ Type: Slit Nozzle Burner

🔹 Models

・ C-CFB-II: For combustion using ambient air

・ H-CFB-II: For combustion using preheated air up to 500℃

🔹Firing Rates

| Model | Firing Rate (kW) |

|---|---|

| CFB-II 13 | 150 |

| CFB-II 25 | 290 |

| CFB-II 38 | 440 |

🔹 Applications

・ Industrial furnaces requiring uniform heating

・ Direct non-oxidizing heating processes

・ Operations demanding stable flat flame distribution

・ Applications with preheated or ambient combustion air

Burner for co-generation system

🔹 Summary

This burner is designed for co-generation systems to enhance steam generating capacity by heating high-temperature, high-pressure exhaust gas from gas turbines. This auxiliary heating significantly improves the overall efficiency of the co-generation system. (Jointly developed with Osaka Gas Co., Ltd.)

🔹 Key Specifications

・ Firing rate: 2,791–25,586 kW

・ Fuel pressure: 34.3 kPa (at burner inlet)

・ Turndown ratio: 10:1

🔹 Features

・ Optimizes utilization of gas turbine exhaust for steam generation

・ Improves overall efficiency of co-generation systems

・ Suitable for a wide range of industrial applications requiring auxiliary heating

Model LS sintering machine ignition furnance burner

🔹 Summary

The Model LS sintering machine ignition furnace burner improves the quality of sintered materials for blast furnaces, enhancing strength, composition, and grain size, while also reducing coke consumption.

🔹 Key Features

・ Ignition furnace burner provides uniform ignition by spraying high-speed, high-temperature combustion gas over the entire surface of the raw material

・ Holding furnace burner allows free adjustment of flame length according to application

・ Contributes to improved sintered material quality and reduced fuel consumption

🔹 Specifications

・ Air pressure: 2.5 kPa

🔹 Models and Firing Rates

| Model | Firing Rate (×kW) |

|---|---|

| LS-10-G | 116 |

| LS-30-G | 349 |

| LS-50-G | 580 |

| LS-100-G | 1160 |

| LS-150-G | 1740 |

| LS-200-G | 2320 |

🔹 Applications

・ Sintering processes in blast furnace operations

・ Industrial applications requiring uniform ignition and controlled flame length

Pilot burner

🔹 Summary

The NPC series and MPN series are nozzle-mix type pilot burners designed to allow installation of a flame detector for reliable ignition monitoring.

🔹 Key Features

・ Nozzle-mix type design

・ Compatible with flame detector installation for safe operation

・ Provides reliable ignition for various industrial applications

🔹 Applications

・ Pilot ignition for larger burners or furnaces

・ Industrial processes requiring monitored and safe ignition

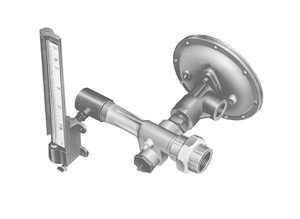

Low pressure inspirator

🔹 Summary

The low pressure inspirator is a mixer that induces and mixes fuel gas using air, allowing precise proportional adjustment by controlling the air side.

🔹 Key Features

・ Mixes fuel gas efficiently using induced air

・ Allows proportional adjustment by controlling the air flow

・ Supports stable and precise combustion

🔹 Applications

・ Industrial burners requiring accurate fuel-air mixing

・ Processes where proportional control of fuel is critical

Model M air gas mixer

🔹 Summary

The Model M air gas mixer is a forced-mixing type that allows proportional adjustment by controlling the air intake. It is suitable for producing large volumes of mixed gas.

🔹 Key Features

・ Forced-mixing design for efficient gas blending

・ Allows proportional adjustment via air intake control

・ Capable of producing large amounts of mixed gas

🔹 Applications

・ Industrial burners and furnaces requiring consistent gas mixing

・ Processes needing large-volume mixed gas production

Ported tube burner for heating glass

🔹 Summary

The ported tube burner is designed for local and continuous line heating of glass in combination with perforated heating tubes, minimizing heat loss caused by exhaust gas.

🔹 Key Features

・ Designed for local and continuous line glass heating

・ Combines with perforated heating tubes for efficient heat transfer

・ Minimizes heat loss from exhaust gas

🔹 Applications

・ Glass manufacturing processes requiring precise and continuous heating

・ Industrial operations aiming to reduce energy loss during heating

MODEL WRBG™RADIANT TUBE BURNER

🔹 Summary

The WRBG™ radiant tube burner reduces NOx emissions through exhaust gas recirculation and two-stage combustion. Preheated air can be used via an insert-type recuperator. Low excess air combustion improves fuel efficiency, while uniform temperature distribution extends the service life of the radiant tube.

🔹 Key Features

・ Reduced NOx emissions via exhaust gas recirculation and two-stage combustion

・ Allows use of preheated air with insert-type recuperator

・ Low excess air combustion enhances fuel savings

・ Uniform temperature distribution extends radiant tube service life

🔹 Applications

・ Industrial furnaces requiring low-emission operation

・ Processes needing efficient fuel usage and uniform heating

・ Operations benefiting from extended radiant tube lifespan

For more details, please contact us

PT CHUGAI RO INDONESIA

✉️ chugairo@n-crid.com

📞 +6221-527-9652